Services

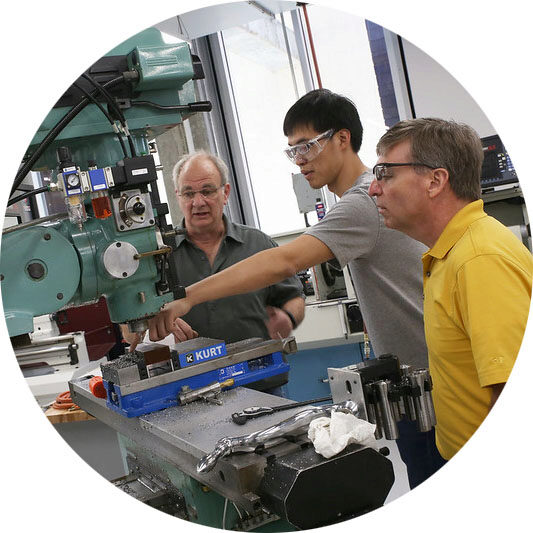

The Montgomery Machining Mall provides the Schools of ME, ECE, BME, MSE and the College of Sciences with research and curriculum support.

- Fabrication of prototype mechanical equipment for research

- Provide safety and operational training on equipment

- Assist in the design/fabrication of research and academic projects

- Provide space and tools for students to learn and explore fabrication techniques

(text and background only visible when logged in)

Equipment

- 8 vertical mills with Proto-Trak 2 Axis CNC control

- 7 toolroom lathes with DRO

- 1 Okuma Genos L250 2 axis CNC lathe

- 2 Haas Super Mini Mill

- 1 Haas VF2 CNC Mill

- 1 Haas TL1 CNC Lathe

- 1 Haas OM1 CNC Mill

- 1 Seibu wire EDM 5 axis

- 1 Okuma Spaceturn 3 axis CNC lathe

- 1 Romi 2 axis CNC lathe

- 1 Proto-Trak 2 axis CNC lathe

- 1 Okuma Millac 3 axis CNC mill

- 1 Starrett HB 400 optical comparator

- 1 Hardinge V480 3 axis CNC mill

- 1 Proto-Trak 3 axis CNC mill

- 1 Zeiss CMM

- 1 Clausing surface grinder

- 1 Marvel vertical band saw

- 2 Do-All vertical band saw

- 1 Accutex CNC sinker EDM

- 1 Titan EDM drill

- 2 Rockwell Drill Press

Training

The Montgomery Machining Mall offers training on manual machine tools each semester. The training consists of 2 classes over 2 weeks, each 2 hours long. The first class is on the belt sander, bandsaw, and manual lathe. The second class is on the knee mill. Both classes include general shop safety and safety on all the machines you’ll be using.

The MMM prioritizes training in the following order: undergraduate coursework (ex. Capstone), graduate research, undergrad research, and then those who are just looking to learn how to use one or more of the machines.

Please register at the link below and if you have any questions contact Nathan Mauldin.

Basic Safety Items to Remember

- Ask for instructions if you are not familiar with the particular machine, tool, or procedure.

- Safety glasses MUST BE WORN AT ALL TIMES.

- Do not operate machinery with loose clothing or jewelry.

- Long hair must be tied back and contained.

- No open toed shoes allowed.

- Clean machinery every time you use it.

- The two person rule is in effect.

- Report any machine that has been damaged. This may keep the next user from getting hurt.

- Please help keep this shop clean and safe. If you abuse the shop, you will lose your privilege to use it.

(text and background only visible when logged in)

Contact Us

The Montgomery Machining Mall has a diverse array of knowledge amongst our staff. Please email or contact the Machine Shop personnel about your specific needs for your job request.

Montgomery Machining Mall: 404.894.2957

Machine Shop Manager: 404.894.3216

Scott Elliott

Machine Shop Manager

Carlos Barrow

Research Coordinator I

Sinker EDM, Coordinate Measuring Machine (CMM)

Frank Murdock

Instrument Maker II

General Machinist, Sheetmetal Fabricator

Denn Agustin

Instrument Maker II

Computer Numerical Control (CNC) Machinist, CNC Router, 3-D Printer

Justin Dean

Instrument Maker III

Welder and Fabricator, General Machinist, Machinery Maintenance

Seth Reed

Instrument Maker II

General Machinist, Waterjet

Ashley Andrews

Mechanical Engineer III

Design and Development, Wire Electrical Discharge Machining (EDM)

Nathan Mauldin

Machine Shop Supervisor I

Training Coordinator